A Control Chart Used To Monitor The Process Mean Is The:

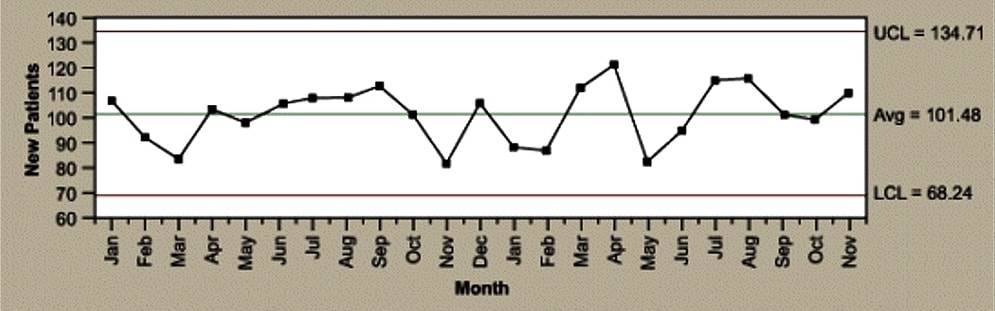

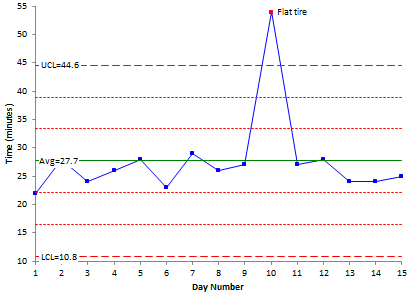

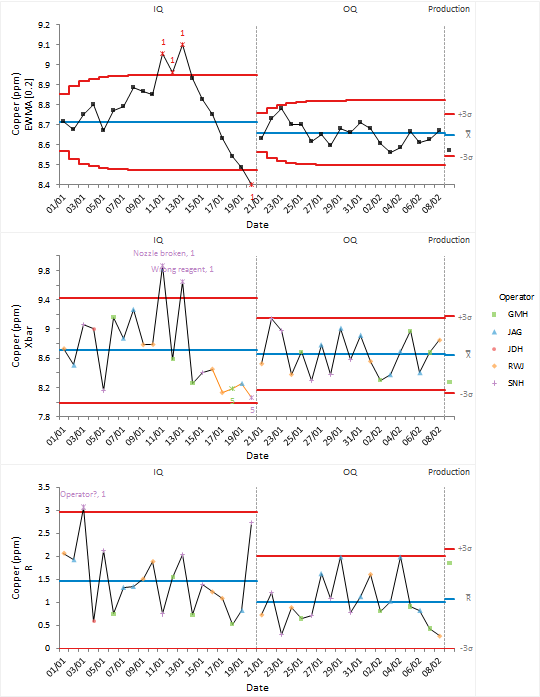

Control charts are used to routinely monitor quality.

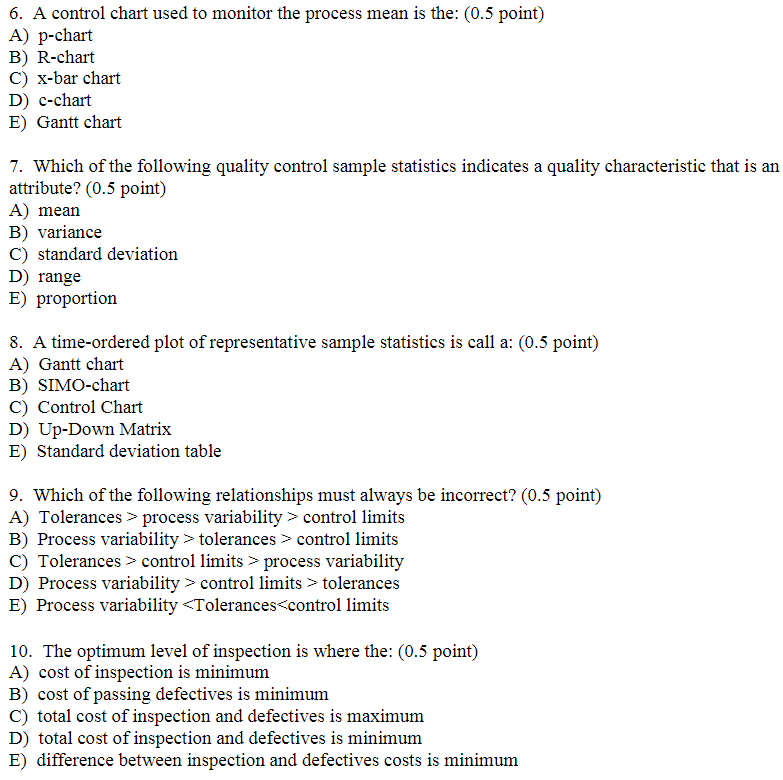

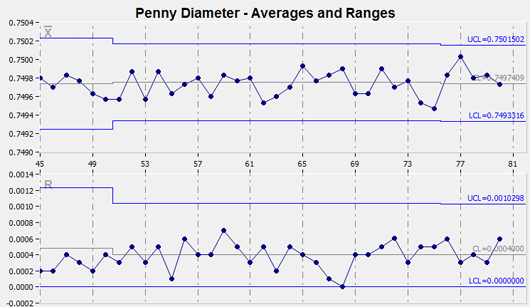

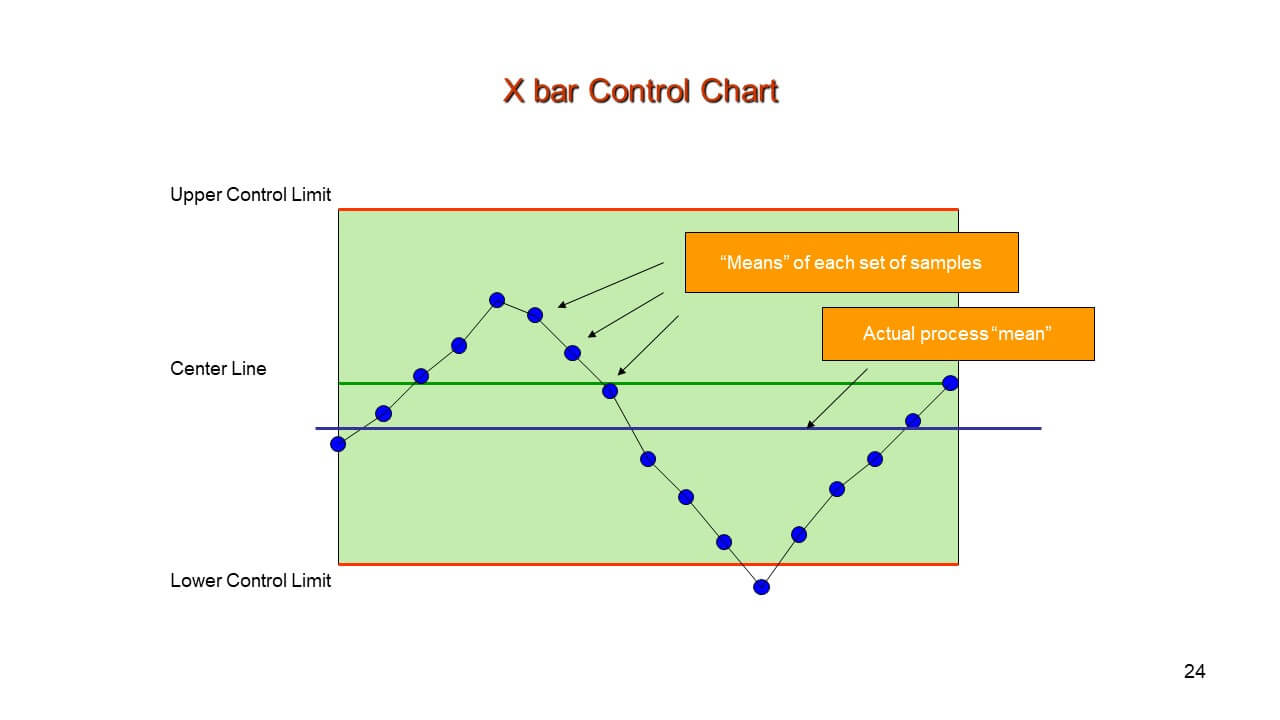

A control chart used to monitor the process mean is the:. A control chart used to monitor the process mean is the. If a point is out of the control limits it indicates that the mean or variation of the process is. The control limits on the X-Bar brings the samples mean and center into consideration.

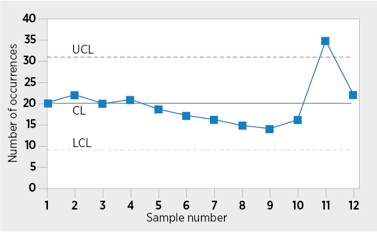

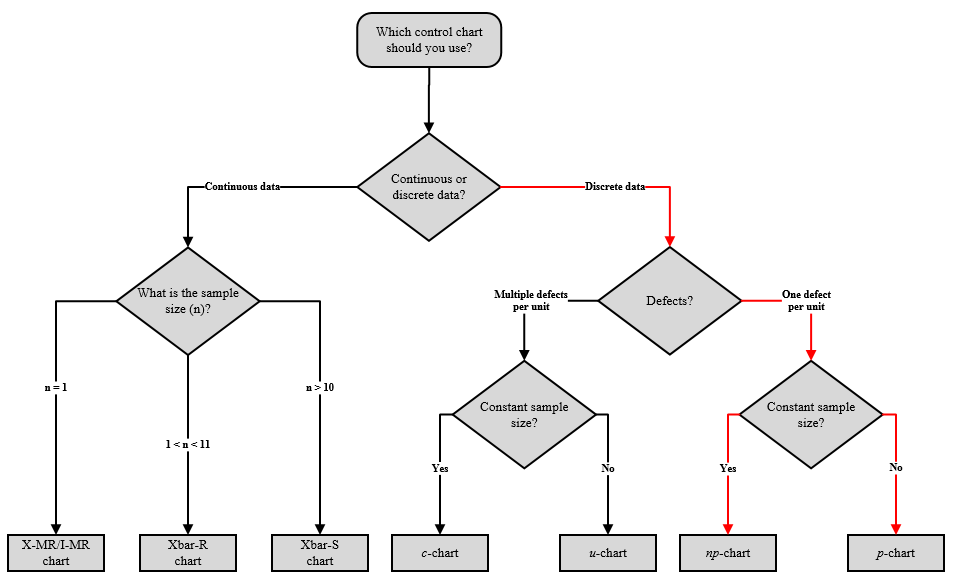

29 The control chart used for the fraction of defective items in a sample is A c-chart. The I chart is used to detect trends and shifts in the data and thus in the process. Number of defects per unit.

As the sample size gets larger the control limits move closer to the true process mean. The range of the process over the time from subgroups values. Control chart rules can vary slightly by industry and by statistician.

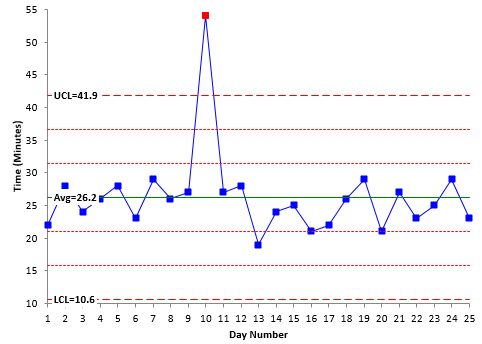

The I-MR control chart is actually two charts used in tandem Figure 7. A control chart used to monitor the process mean is the. D All of the above.

A point which is outside of the lower control limit on an R-chart. The control chart used to monitor the process mean is known as Select one. Grant chart O d.